Our agricultural fabric belts serve as the basis for a broad range of applications for the harvesting of beets, potatoes and many other types of vegetable.

Our high-quality base belt is cut to the correct width and assembled by our customers. They also undertake the profiling of the belt. Our customers also perform the processing steps, such as the assembly of joiners and metal rods.

Thanks to the high breaking strength and high adhesion offered by our fabric inlays, the 3-ply carcass guarantees a long service life, even under the most demanding of conditions.

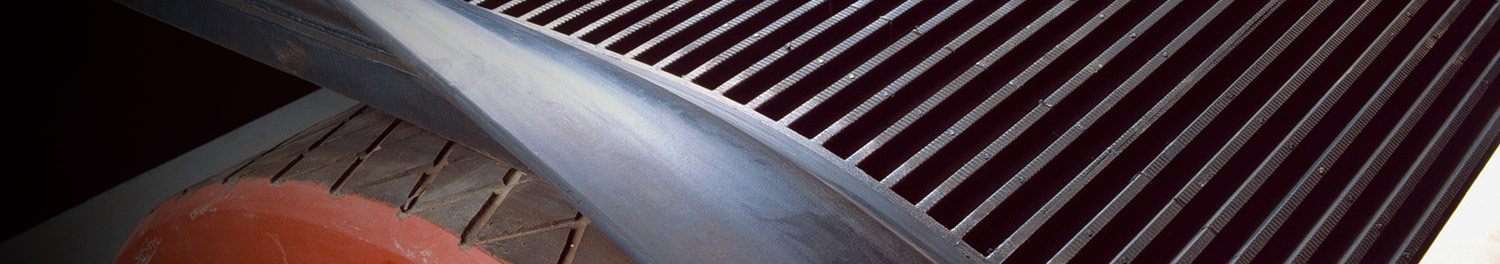

One of our unique selling points is our continuous vulcanization process. Unlike conventional discontinuous vulcanization, our continuous vulcanization process ensures excellent uniformity of the top and bottom belt surfaces.