Belt Mistracking

The following six chapters clearly demonstrate how to mount and splice steel cord conveyor belts. Using the mouse, simply click the desired chapter.

-

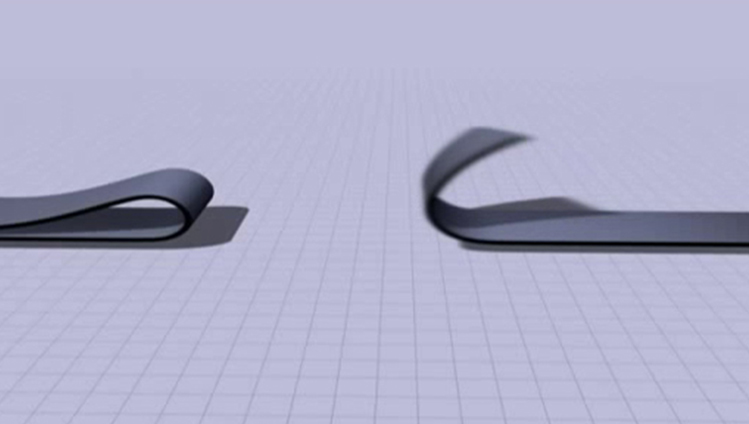

1. Aligning the Belt Ends

-

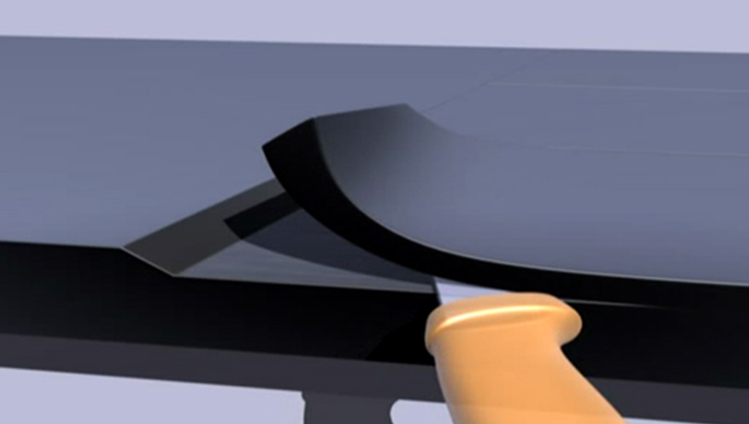

2. Stripping Away the Cover Stock

-

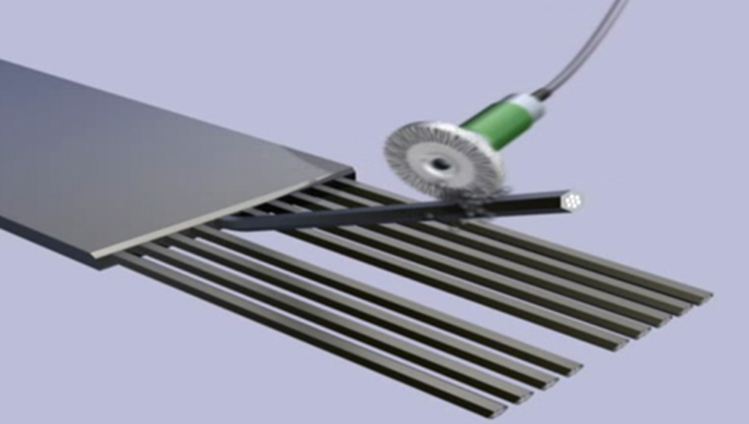

3. Isolating Individual Cables

-

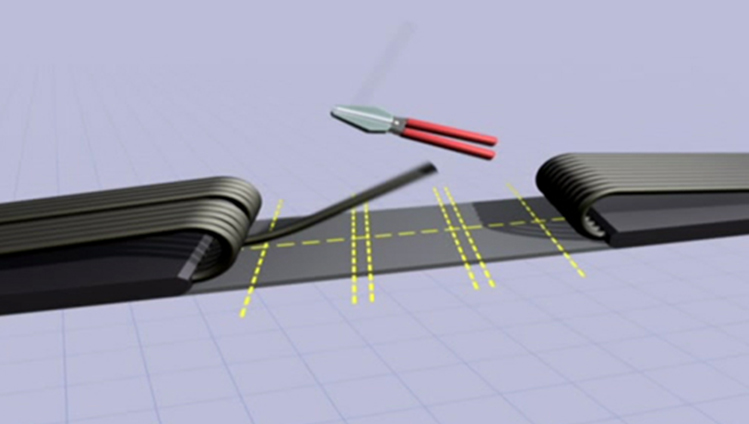

4. Assembling the Cables

-

5. Closing the Splice

-

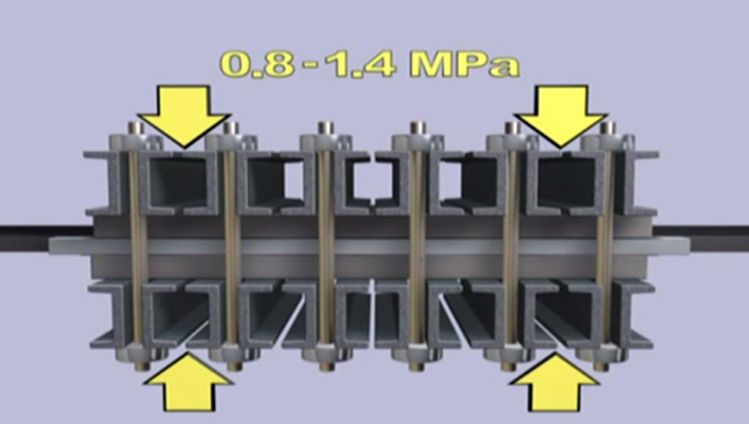

6. Vulcanizing the Splice