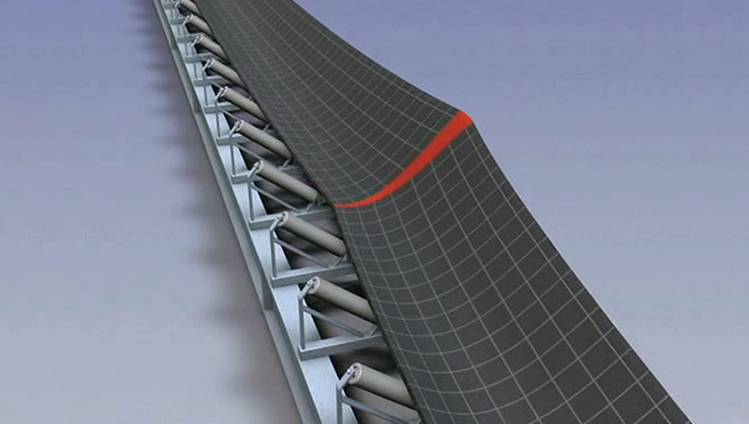

Causes of Belt Mistracking

A good and exact alignment contributes to good tracking of the conveyor belt. True alignment of the idlers improves the running behaviour of the belt and decreases the energy consumption of the belt each idler station.

In the following 9 chapters several possible causes for the mistracking of a conveyor belt in the conveyor are demonstrated.

-

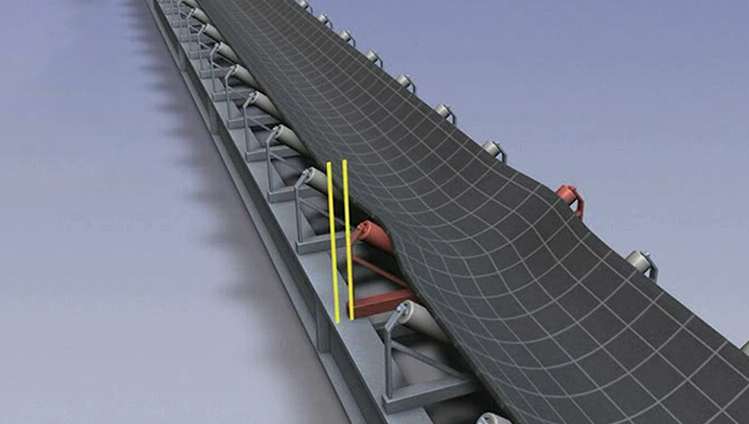

1. Idler Station out of True Alignment

-

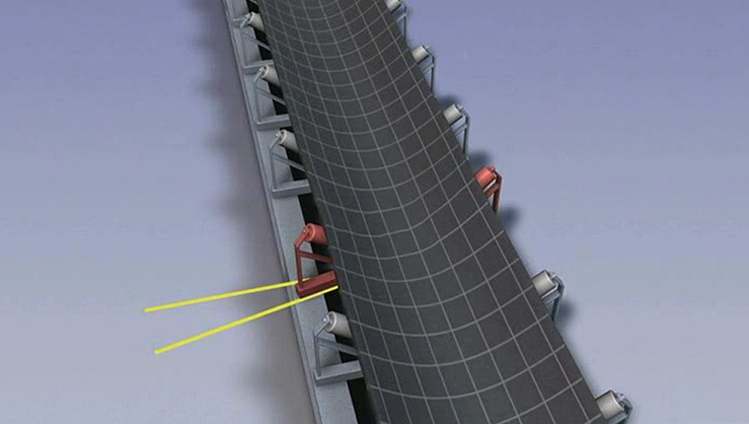

2. Idler Station Rotated Horizontally

-

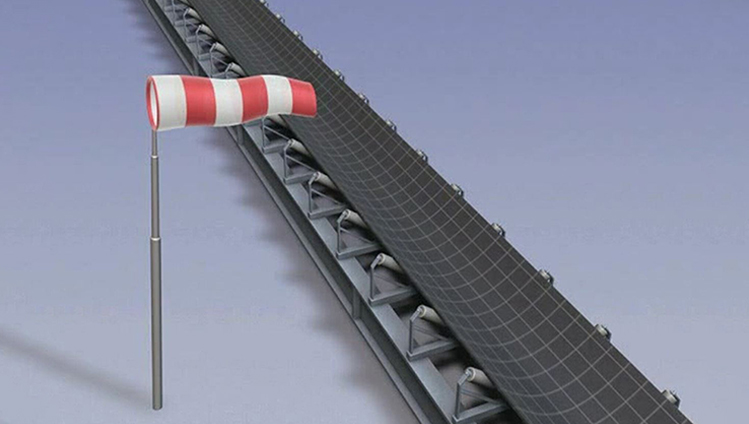

3. Belt Conveyor in Wind from the Side

-

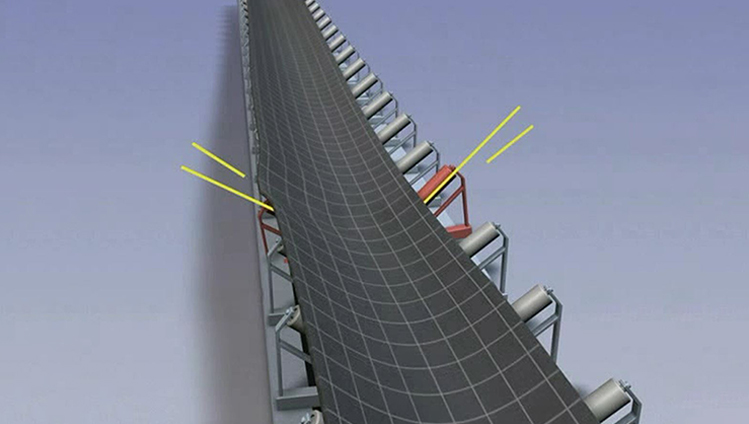

4. Idler Station Rotated Vertically

-

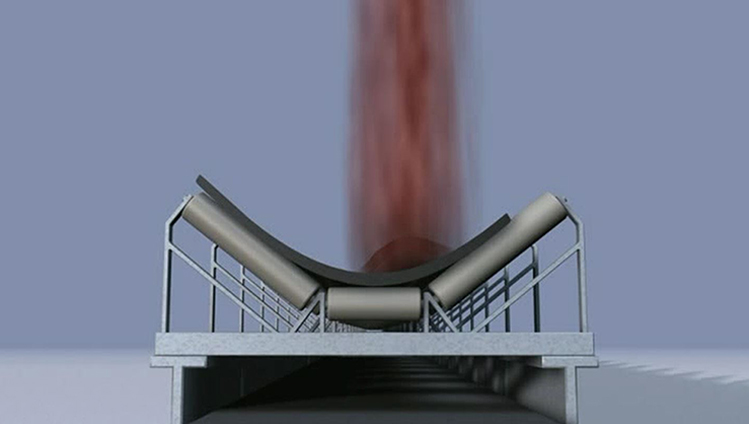

5. Influence of the Loading of the Bulk Material

-

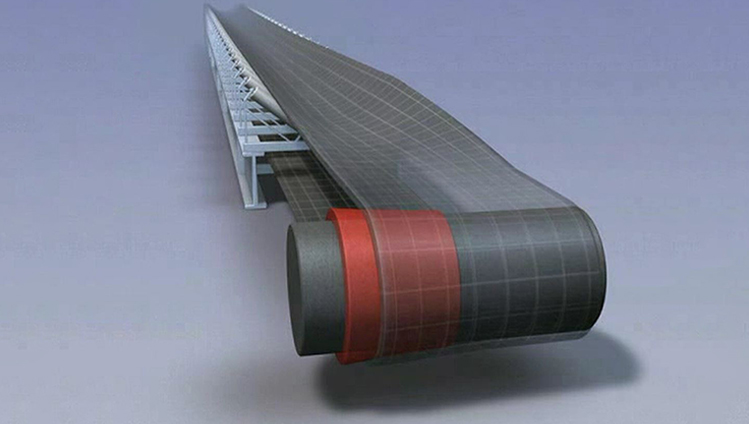

6. Material Sticking to one Side of the Pulley

-

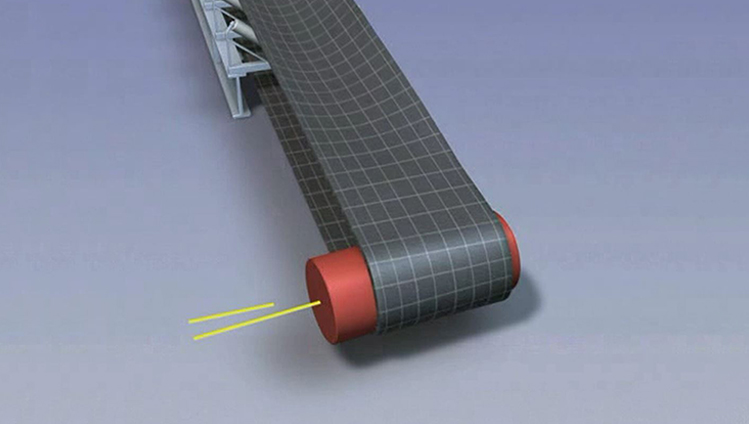

7. Pulley not Perpendicular to Belt Running Direction

-

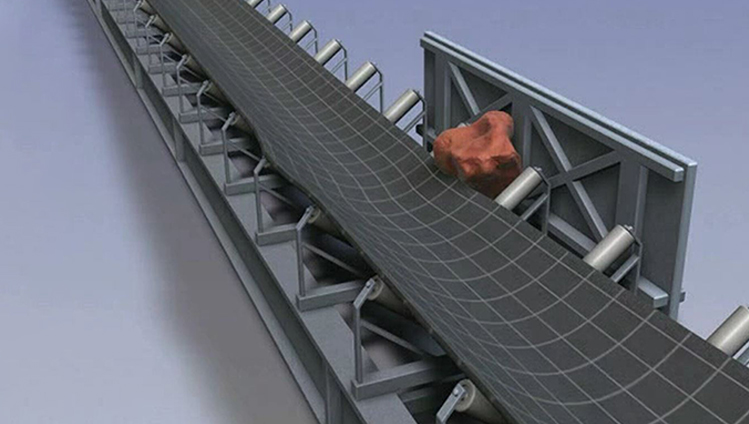

8. Foreign Object Stuck in Conveyor Structure

-

9. Badly Aligned Belt Splice