- Products & Solutions

- Compounds & Sheetings

- Conveyor Belt Systems

- Fluid Handling

- Power Transmission

- Printing Technology

- Sealing Systems

- Surface Materials

- Suspension & Anti-Vibration

- Automotive Technologies

- Tires

- Industries

- Agriculture & Forestry

- Aerospace

- Construction

- Energy Management

- Food Chain Processing

- Home, Garden & Leisure

- Material Handling

- Mechanical & Plant Engineering

- Mining

- Industrial Safety

- Printing

- Rail Transport

- Ships, Ports & Sea

- Two Wheelers

- Commercial Vehicles

- Passenger Cars

- Media

- Press

- Stories

- Social Media

- Awards

- Fairs & Events

- Document Center

- Compounds & Sheetings

- Rubber Compounds

- Elastomer Sheeting

- Conveyor Belt Systems

- Material Handling

- Processing & Special Belts

- Conveyor Services

- Fluid Handling

- Passenger Cars

- Commercial Vehicles

- Industrial Vehicles

- Two-Wheelers

- Collapsible Tanks

- Industrial Hoses

- Hydraulic Hoses

- Oil & Gas Hoses

- Renewable Energy Solutions

- Crimper

- Power Transmission

- Commercial Vehicles OE

- Passenger Cars OE

- Drive Belts Automotive Aftermarket

- Agriculture vehicles & machines

- Industrial Applications

- Motorbike Drive Belts

- Printing Technology

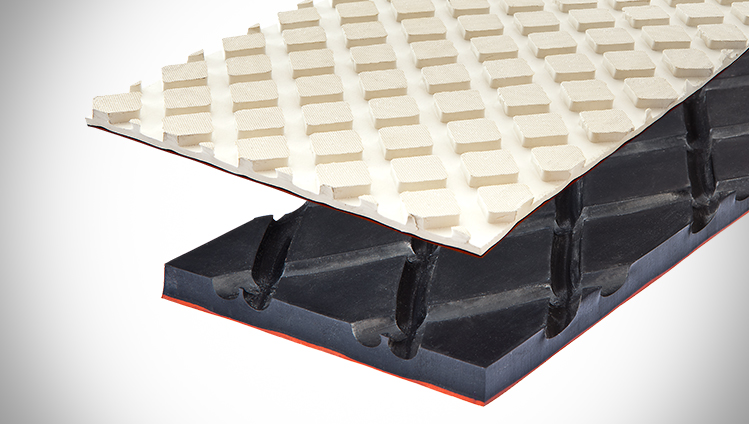

- Printing Blankets

- Flexo Printing Plates

- Coating / Varnishing

- Sealing Systems

- Vehicle Applications

- Industrial Applications

- Surface Materials

- Mobility & Transportation

- Living Spaces

- Protection & Health

- Mechanical Engineering

- Sustainable Surfaces

- Surface Technologies

- Design

- Services & Tools

- Coil Coating

- Suspension & Anti-Vibration

- Passenger Cars

- Light Trucks

- Commercial Vehicles

- Industrial Vehicles

- Marine

- Machines & Equipment

- Railway

- Commercial Vehicles OE

- Accessory Belt Drive

- Fan Drive

- Mild Hybrid

- Mobility & Transportation

- Passenger Cars

- Commercial Vehicles

- Agricultural Vehicles

- Construction Vehicles

- Material Handling Vehicles

- Marine

- Railway

- Passenger Cars

- Interior

- Chassis & Body

- Powertrain

- eMobility

- Passenger Cars

- Interior

- Chassis & Body

- Exhaust Gas System

- Powertrain

- eMobility

- Vehicle Applications

- Brake Systems

- Chassis

- Steering Gear

- Engine Management

- Low-friction Elastomers for Seals

- Printing Blankets

- CONTI-AIR® Blanket Technology

- PHOENIX Xtra Blankets

- Vulcan

- Rollin

- Printec

- Sava

- Material Handling

- Steelcord Conveyor Belts

- Textile Conveyor Belts

- Steep Incline Conveyor Belts

- Enclosed Conveyor Belts

- Solid Woven Conveyor Belts

- Steel Mesh Conveyor Belts

- Passenger Cars OE

- Accessory Belt Drive

- Mild Hybrid

- Camshaft Drive

- Oil Pump Drive

- Water Pump Drive

- Steering Drive

- Brakes

- Body Control

- Interior Drives

- Systems Expertise

- Commercial Vehicles

- Cabin & Interior

- Chassis & Body

- Exhaust Gas System

- Powertrain

- eMobility

- Storage and Transport of Liquids

- Flexo Printing Plates

- CONTI Laserline

- Axcyl

- Light Trucks

- Axle Air Springs

- Hydro Bodymounts

- Living Spaces

- Interior Design

- Home Decoration

- Exterior Design

- Industrial Applications

- Elastomer Sheeting

- Expansion Joints

- Diaphragms

- Diaphragm Materials

- Gas Holder Diaphragms

- Processing & Special Belts

- Drive & Movement

- Filtering & Draining

- Seeding & Harvesting

- Conveyor Services

- Field Service

- Digital Solutions

- Service Material

- Technical Consulting & Training

- Tools & Equipment

- Accessories & Components

- Commercial Vehicles

- Cabin & Interior

- Chassis & Body

- Powertrain

- Air Spring Replacement

- Industrial Vehicles

- Cabin & Interior

- Chassis & Body

- Exhaust Gas System

- Powertrain

- Protection & Health

- Protective Equipment Materials

- Medical Films

- Upholstery Material

- Agriculture vehicles & machines

- AGRIDUR® Drive Belts

- Industrial Vehicles

- Cabin & Interior

- Chassis & Body

- Powertrain

- Two-Wheelers

- Cooling Water Lines

- Fuel Supply Lines

- Oil Lines

- Hoses for Electric Drives

- Tank Ventilation & Degas Lines

- Mechanical Engineering

- Weaving Beam Coverings

- Gas Holder Diaphragms

- Drop Thread Material

- Diaphragm Materials

- Industrial Applications

- Drive Belts

- Friction Rings & Wheels

- Collapsible Tanks

- Collapsible Fuel Tanks

- Storage and Transport of Liquids

- Marine

- Couplings

- Engine Mounts

- Industrial Hoses

- Air & Multipurpose Hoses

- Chemical Transfer & Petroleum Hoses

- Data Cooling Hoses

- Food & Beverage Hoses

- Marine Hoses

- Material Handling, Dredge & Mining Hoses

- Specialty Hoses

- Steam & Cleaning Hoses / Equipment

- Vacuum Hoses

- Water Hoses

- Welding & Gas Hoses

- Machines & Equipment

- Mounts

- Couplings

- Air Actuators/Pneumatics

- Air Springs/Isolation

- Expansion Joints

- SAM Spring

- Motorbike Drive Belts

- Heavy-Duty Timing Belts

- Variable Speed Belts

- Sustainable Surfaces

- Sustainable Surfaces for Mobility

- Railway

- Bogie

- Body & Interior

- Powertrain

- Surface Technologies

- staynu® Technology

- laif® Technology

- cool colors Technology

- Hydraulic Hoses

- Constant Pressure

- Maximum Abrasion Resistance

- Extreme Temperature

- Standard

- Special Applications

- Push-on Hoses

- Thermoplastic

- Oil & Gas

- Design

- Trends

- Collections

- Projects

- Oil & Gas Hoses

- Production Flexible Lines

- Drilling Hoses

- Well Service Hoses

- Marine Hoses

- Services

- Rig Supply Hoses

- Renewable Energy Solutions

- Big Bubble Curtain Hose

- Hydraulic Hoses for Wind Turbines

- Hydrogen Hoses for Bunkering

- Marine Hoses for Liquified Ammonia Transfer

- Carbon Capture and Storage

- Services & Tools

- Surface Processing

- Digital Printing

- Coil Coating

- Foodsafe Films

- Interior Design

- Artificial Leather

- Furniture Films

- Interior

- Air Conditioning Unit

- Cabin & Interior

- Air Conditioning Unit

- staynu® Technology

- Artificial leather with staynu® technology

- Automotive | staynu® Technology

- Bogie

- Primary Suspension

- Secondary Suspension

- Auxiliary Systems

- Wheel Springs

- Refurbishment Service

- Cabin & Interior

- Vibration Absorbers

- Seat Air Springs

- Cab Air Springs

- Electronic Air Spring Damping System

- Protective Equipment Materials

- Chemicals & Gases

- Dry Suit Materials

- Canvas / Tarpaulin Materials

- Passenger Cars

- Instrument Panel

- Door/Side/Center Console

- Pillar/Panel/Storage Areas

- Sun Visor

- Seat Cover/Headrest

- Seat Backs

- Floor Covering

- Rear Tray

- Cargo Compartment Cover

- Services

- Accessory Belt Drive

- CONTI® HEAVY DUTY POWER

- CONTI® UNIPOWER CV

- CONTI® UNIPOWER ECO₂-FLEX CV

- CONTI® UNIPOWER TOUGH GRIP CV

- CONTI®V FO PIONEER

- CONTI®V MULTIBELT

- Accessory Belt Drive

- CONTI® UNIPOWER

- CONTI® UNIPOWER TOUGH GRIP

- CONTI® UNIPOWER ELASTIC

- CONTI® UNIPOWER ECO₂-FLEX

- Cabin & Interior

- Seat Air Springs

- Electronic Air Spring Damping System

- Interior

- Vibration Absorbers

- Chassis & Body

- Active Chassis Stabilization

- Power Steering

- Connections

- Body & Interior

- Air Actuators for Pantograph

- Seat Suspension

- Drive Belts for Door Opening

- Wheel Springs

- Chassis & Body

- Air Actuators/Pneumatics

- Axle Air Springs

- Cab Air Springs

- Bushings

- Sandwich Mounts

- Cab Mounts

- Bump Stops

- Chassis & Body

- Brake System

- High & Low-Pressure Hydraulics

- Auxiliary Hydraulic Drive

- Hydrostatic Fan Drive

- Power Steering

- Chassis & Body

- Cab Mounts

- Axle Air Springs

- Bushings

- Door Stop Bumpers

- Vibration Absorbers

- Chassis & Body

- Spring Strut Mounts

- Bushings

- Vibration Absorbers/Dampers

- Crossmember

- Exhaust Hangers

- Fan Drive

- CONTI® HEAVY DUTY POWER

- CONTI® UNIPOWER CV

- Mild Hybrid

- CONTI® UNIPOWER HP

- CONTI® UNIPOWER XHP

- Home Decoration

- d-c-fix

- Commercial Vehicles

- Instrument Panels/Doors

- Pillars/Panels/Resting Area

- Storage Area/Shelfs

- Seat Covers/Headrests

- Seat Backs

- Sun Visors

- Floor Covering

- Powertrain

- Torque Rods/Torque Strut

- Gear Box Mounts

- Hydraulic Mounts

- Adaptive Mounts

- Adaptive Engine Mounts

- Active Mount Systems

- Propshaft Bearings

- Exterior Design

- Exterior Films

- Artificial Leather

- Press Polished Vinyl

- Pool Liner

- Vinyl Deck Membrane

- Resilient Flooring

- Cabin & Interior

- Air Conditioning Unit

- cool colors Technology

- Artificial leather with cool colors technology

- Exterior films with cool colors technology

- Digital Solutions

- Conveyor Monitoring Systems

- Conveyor Inspection Services

- Belt Monitoring Systems

- Conti+ Conveyor Data & Software

- Drive Belts

- V-Belts

- Poly-V-Belts

- Synchronous Belts

- Flat Belts

- Specialty Belts

- Components

- Service

- Camshaft Drive

- CONTI® BASIC RUNNER

- CONTI® DIESEL RUNNER

- CONTI® COLD RUNNER

- CONTI® BELT IN OIL (BIO)

- Mild Hybrid

- CONTI® UNIPOWER HP CV

- Exhaust Gas System

- SCR System/Urea

- Exhaust Gas Return

- Control Functions

- Powertrain

- Mounting Elements

- Couplings

- Vibration Absorbers/Dampers

- Torque Supports

- Powertrain

- Couplings

- Engine Mounts

- Agricultural Vehicles

- Cover Material

- Floor Covering

- Door/Side/Instrument Panels

- Powertrain

- Engine Mounts

- Propshaft Bearings

- Exhaust Gas System

- Particulate Filter

- SCR System/Urea

- Service Material

- Adhesives, Solutions & Solvents

- Belt Maintenance & Repair

- Splice Material

- Chassis & Body

- Couplings/Quick Connection

- Brake System

- High & Low-Pressure Hydraulics

- Power Steering

- Auxiliary Hydraulic Drive

- Hydrostatic Fan Drive

- Powertrain

- Compressor/Compressed Air

- Fuel Supply

- Ventilation & Degassing

- Heating & Cooling

- Charge Air

- Turbocharger Supply

- Oil Cooling

- Clutch

- Powertrain

- Fuel Supply

- Heating & Cooling

- Charge Air

- Dirty/Clean Air Supply

- Turbocharger Supply

- Transmission Oil Cooling

- Engine Oil Cooling

- Ventilation & Degassing

- Oil Pump Drive

- CONTI® BELT IN OIL (BIO)

- Construction Vehicles

- Seat Cover

- Floor Covering

- Door/Side/Instrument Panels

- Marine Hoses

- Hoses for FPSO Tandem Offloading Service

- Hoses for SPM Service

- Hoses for FPSO Seawater Intake Systems

- Hoses for Ship-to-Shore Service

- Hoses for CBM/MBM Service

- Hoses for Ship-to-Ship Service

- Hoses for Refined Products and Other Chemicals

- Hose Ancillary Equipment

- Hose System Design Services

- eMobility

- Motor Mount Systems

- Water Pump Drive

- CONTI® WAPU RUNNER

- Material Handling Vehicles

- Seat Cover Materials

- Floor Coverings

- Door/Side/Instrument Panels

- eMobility

- Thermal Management Solutions

- Fuel Cell Applications

- eMobility

- Thermal Management Solutions

- Fuel Cell Applications

- Exhaust Gas System

- Particulate Filter

- SCR System/Urea

- Rig Supply Hoses

- Bulk Transfer Hoses

- Utility Hoses

- Hydraulic Hoses

- Chemical Hoses

- Couplings

- Powertrain

- Fuel Supply

- Compressor/Compressed Air

- Ventilation & Degassing

- Heating & Cooling

- Charge Air

- Turbocharger Supply

- Oil Cooling

- Clutch

- eMobility

- Marine

- Life Raft Materials

- Boat Materials

- Seat Upholstery

- Metal Lamination Film

- Press Polished Vinyl

- Steering Drive

- CONTI® SLT POWER

- Brakes

- CONTI® SLT POWER

- Railway

- Seat Upholstery

- Folding Bellow Material

- Body Control

- CONTI® SLT POWER

- Interior Drives

- CONTI® SLT POWER