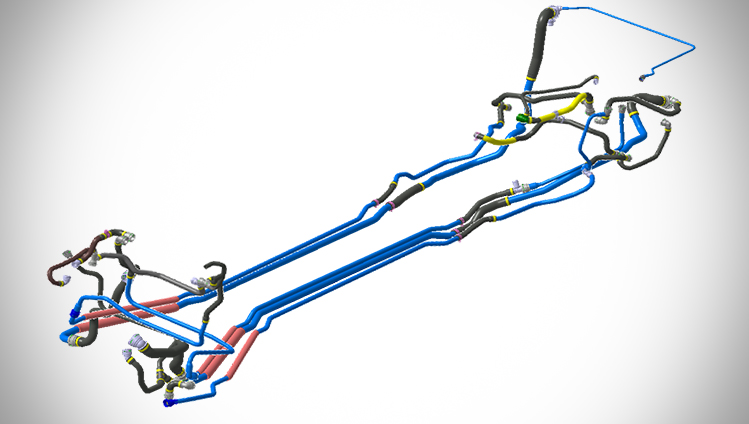

A joint venture, named JoinPlas, between Continental and system supplier aft automotive impressed the jury of the 18th Materialica Design + Technology Award with its modular plastic coupling system for thermal management in vehicles. The award-winning clutch system saves on materials, reduces weight and optimizes flow in vehicles with both electric drives and combustion engines. The jury awarded the system first place in the “Process” category.

Future-oriented concept for battery air conditioning

The jury of the Materialica Award 2020 were most impressed by the intelligent use of existing components and the modular design of the JoinPlas coupling system as well as the simplified production process and future-oriented concept for battery air conditioning. The jury lavished praise stating “This CO2-efficient solution is pioneering for mobility of the future.” This is because the clutch system reduces CO2 emissions not only in applications where weight savings result directly in a reduced fuel consumption but particularly in combustion engines. The material savings reduces the need for resources and results in higher CO2 reductions during production.

The Materialica Award was presented at the eMove360° Hybrid international trade fair for electric mobility and autonomous driving in Munich, Germany, which recognizes new products and concepts characterized by a perfect combination of intelligent material selection, outstanding engineering performance, a high degree of innovation and impressive design.