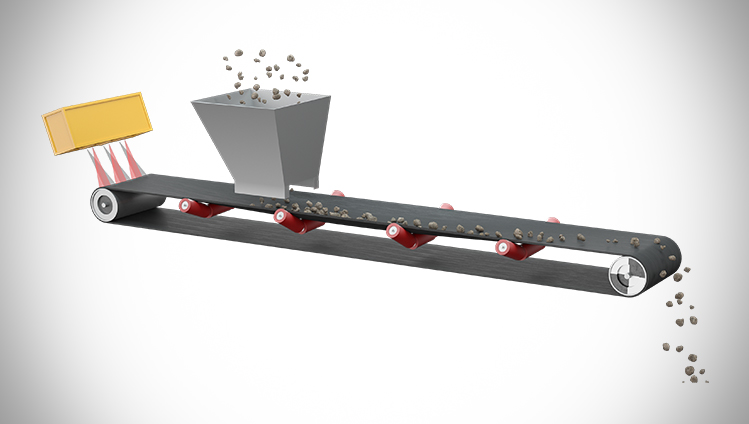

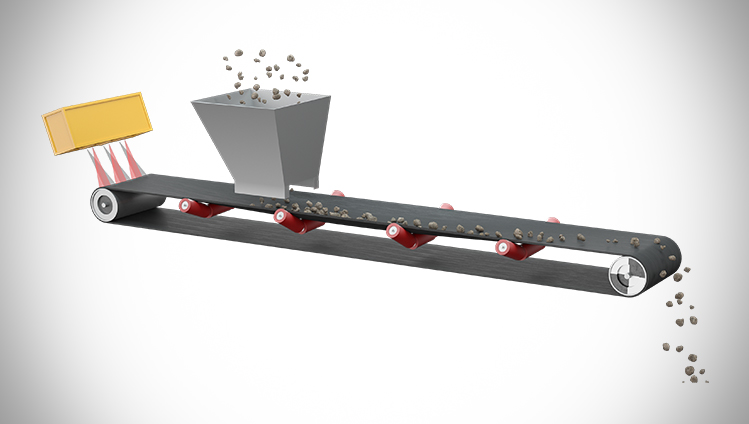

CONTI SurfaceProtect is a laser-based system that continuously monitors the surface of the conveyor belt. The system evaluates the cover condition for cuts, and gouges or large impact damage events. Data is analyzed and reported with the position and size of all surface damages.

Application

The CONTI SurfaceProtect system is used in industrial and mining belt conveying applications. The system uses line laser profile sensors for scanning the entire surface of the belt. The recorded cover condition is analyzed online via smart image processing so that if surface damages such as abnormal abrasive wear or impact defects occur, they can be reported at any time. The conveyor belt surface is inspected automatically, even in difficult-to-access conveyors for all types of belts. The belt profile information can be used for various purposes such as remaining lifetime estimation or as pre-analysis for manual belt inspection and repairs.

Functionality

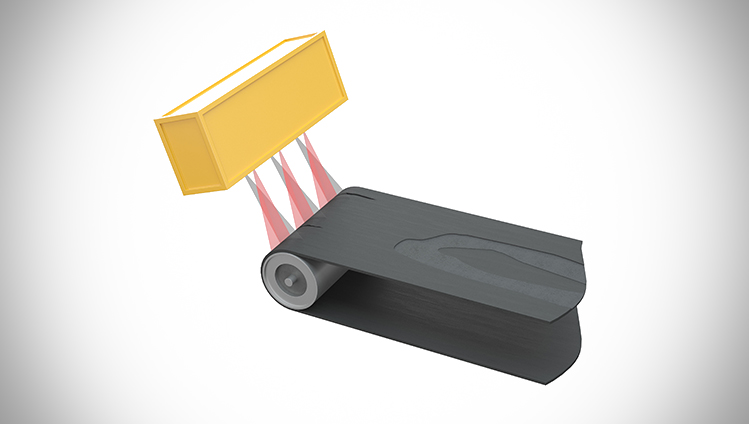

- Use of profile sensors (line laser and optical sensor)

- Laser line is projected on running conveyor belt surface

- Laser line follows the real profile of the belt cover

- Optical sensor records shape and position of the laser line

- Software compiles laser data into a digital belt map

- Digital map is analyzed with variable defect thresholds

Top Cover Monitoring Unit

- High-resolution, non-contact 3D measurement

- Full or partial belt width cover scan

- User-defined thresholds for damage detection

- Large impact defects

- Slit, cut and gouge events

- Edge damage or misalignment

- Splice surface control

- Abnormal abrasion

Technical Key Data

| Height Resolution |

0.1 mm @ 6 m/s belt speed |

| Belt Type and Size |

all available flat steel cord and textile belts |

| Belt Speed |

up to 10 m/s (higher speed with lower resolution) |

| Laser Class |

3B |

| Scan Rate |

up to 3 kHz |

| IP Class |

67 of sensor |

| Operating Temperature |

0 °C – 50 °C (operation below 0 °C is possible with additional heater) |

| Power Supply |

110 – 240 V / 50 – 60 Hz |

| Customized Output |

Relay, Ethernet TCP/IP, Modbus TCP, PROFIBUS |

Got questions?

Contact us!